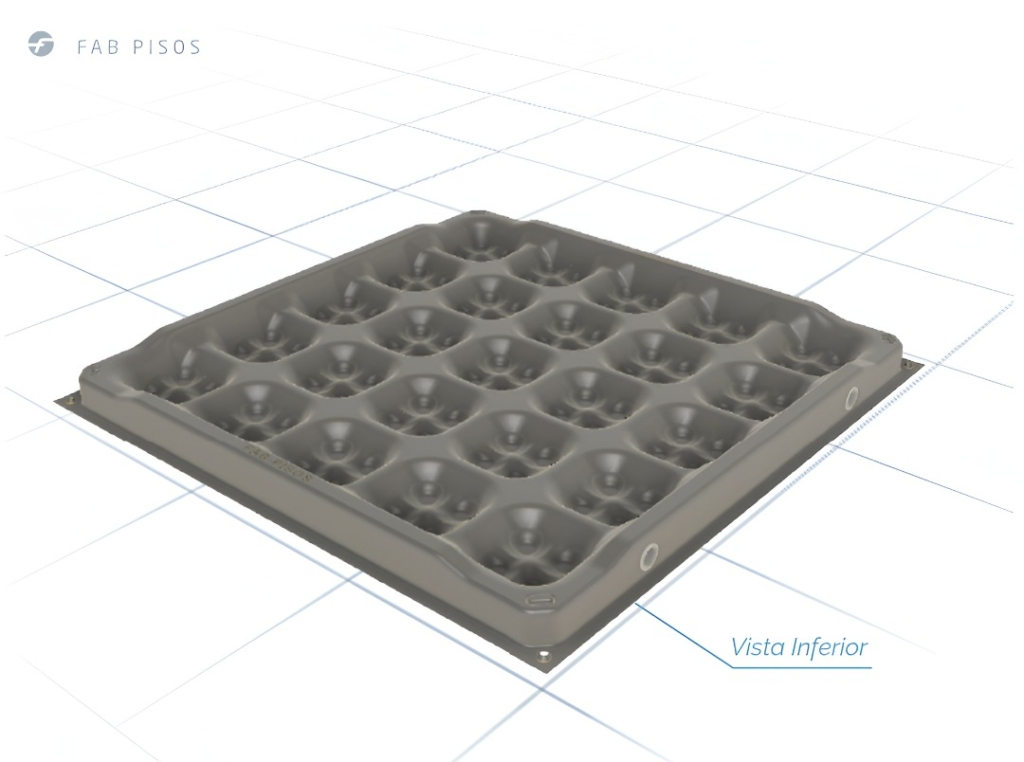

The Fab raised floor panel is composed of two Cold Rolled carbon steel sheets, with the top face being high hardness and the bottom one SAE1006 EEP, featuring 25 aligned structural domes with a small flat area for better weld point application.

These embossments are cold-formed, providing a combination of structural strength and flatness. The sheets are joined through a welding process with 180 points, forming a “sandwich”-type panel that follows a logical square-patterned sequence.

The four bottom corners have stamped projections designed for positive support and fit into the oblong-shaped crosshead, ensuring optimal locking and squareness. To prevent squeaking on floors, four holes and a cut are made simultaneously during the production line.

The anti-corrosion treatment is performed by a robotic system applying electrostatic powder coating and phosphating with phosphoric acid, ensuring high surface protection, adhesion, and uniform coating, with a minimum layer thickness of 50 microns.

The panels are internally filled with lightweight cellular concrete in a homogeneous manner through an automated process, ensuring complete and uniform filling.

The main feature is its 40mm thickness. Additionally, for better fitment, the support has been enhanced to make contact with both the concrete region and the flaps, increasing stability, preventing buckling, and providing greater robustness, effective acoustic dissipation, and durability.